|

Oil Transportation

-

Waterborne Transportation

-

Shipping Costs

-

Oil Spills

-

Storage Facilities

-

Oil Pipelines

-

The Keystone XL Pipeline

-

Crude Oil Rail Shipments

-

World Oil Transit Chokepoints

-

In the News

-

References

How Are Crude Oil and Refined Products Transported?

Crude oil must be moved from the production site to refineries and from refineries to consumers. These movements are made using a number of different modes of transportation. Crude oil and refined products are transported across the water in barges and tankers. On land crude oil and products are moved using pipelines, trucks, and trains. Crude oil must be moved from the production site to refineries and from refineries to consumers. These movements are made using a number of different modes of transportation. Crude oil and refined products are transported across the water in barges and tankers. On land crude oil and products are moved using pipelines, trucks, and trains.

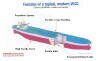

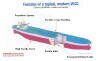

Crude oil tankers are used to transport crude oil from fields in the Middle East, North Sea, Africa, and Latin America to refineries around the world. Product tankers carry refined products from refineries to terminals. Crude oil tankers are used to transport crude oil from fields in the Middle East, North Sea, Africa, and Latin America to refineries around the world. Product tankers carry refined products from refineries to terminals.

Tankers range in size from the small vessels used to transport refined products to huge crude carriers. Tanker sizes are expressed in terms of deadweight (dwt) or cargo tons. The smallest tankers are General Purpose which range from 10 to 25,000 tons.

These tankers are used to transport refined products. The Large Range and Very Large Crude Carriers (VLCC) are employed in international crude oil trade. The size of tanker that can be used in any trade (commercial voyage between a port of origin and destination) is dependent on the tanker's length and loaded depth and the size of the loading and unloading ports.

The larger ships are used because they reduce the cost to transport a barrel of crude oil.

As of 2006:

|

The world tanker fleet had 4,186 vessels with a carrying capacity of 358.8 Mdwt.

|

|

84% of the tanker fleet were owned by independent tanker companies.

|

|

The average age of the fleet was 11.9 years.

|

|

68% of the vessels are double hull ships.

|

Click on the link to see tanker video - Shipping is Big Business. Click on the link to see tanker video - Shipping is Big Business.

Go to the Topic Listing Go to the Topic Listing

Shipping Costs

The following table illustrates the costs between different locations.

|

Source

|

Discharge

|

Cargo

|

Cargo Size,

Thousand

Barrels

|

Worldscale

Rate

|

Freight

Costs, $/B

|

|

Caribbean

|

New York

|

Distillate

|

200

|

215

|

2.46

|

|

Caribbean

|

Houston

|

RFO

|

380

|

70

|

0.90

|

|

Caribbean

|

Houston

|

RFO

|

500

|

73

|

0.94

|

|

N. Europe

|

New York

|

Distillate

|

200

|

158

|

2.91

|

|

N. Europe

|

Houston

|

Crude Oil

|

400

|

82

|

2.22

|

|

West Africa

|

N. Europe

|

Crude Oil

|

910

|

71

|

1.60

|

|

West Africa

|

Houston

|

Crude Oil

|

910

|

74

|

2.27

|

|

Persian Gulf

|

Houston

|

Crude Oil

|

1,900

|

36

|

2.08

|

|

Persian Gulf

|

Japan

|

Crude Oil

|

1,750

|

48

|

1.61

|

|

Persian Gulf

|

N. Europe

|

Crude Oil

|

1,900

|

36

|

1.51

|

[Source: Average data for February 2009 as published in the Oil & Gas Journal from Drewry Shipping Consultants Ltd.]

As illustrated in the above chart, types of cargo and distance determined freight rates.

Note the different costs for distillate deliveries to New York from the Caribbean and N. Europe.

Also see the differences among shipments of crude oil to Houston from N. Europe, West Africa and the Persian Gulf.

The size of the ship used also affects costs as seen by the costs to deliver RFO (residual fuel oil to Houston from the Caribbean.

Go to the Topic Listing Go to the Topic Listing

Although they get most of the publicity, oil spills only account for 12% of all spills. The major cause of ocean oil pollution is industrial waste (61%). Tanker accidents contribute 5% and tanker operations account for 7%. Other shipping accounts for 14%. Better operations and improved ship design have helped reduce the number of large spills. During the decade from 1985-1994, the frequency of large spills declined by 57%. Although they get most of the publicity, oil spills only account for 12% of all spills. The major cause of ocean oil pollution is industrial waste (61%). Tanker accidents contribute 5% and tanker operations account for 7%. Other shipping accounts for 14%. Better operations and improved ship design have helped reduce the number of large spills. During the decade from 1985-1994, the frequency of large spills declined by 57%.

Although the Exxon Valdez gets blame for the "world's largest oil spill," it's only the 52nd biggest spill. Iraq's Saddam Hussein gets the "credit" for the largest. Although the Exxon Valdez gets blame for the "world's largest oil spill," it's only the 52nd biggest spill. Iraq's Saddam Hussein gets the "credit" for the largest.

U.S. tankers are constructed and operated under strict regulations. Companies use a communication network of telephone, telex, and satellite systems to locate their tankers. On board the ships, crews follow strict safety measures, minimizing loss of personnel and product. Automatic collision avoidance systems track approaching ships, alerting a tanker to an obstruction on its course.

There have been many developments in improving the tanker operations to reduce the frequency and amount of oil spilled. At one time, tankers discharged dirty ballast water (oil mixed with sea water into the ocean). Improvements have been made in tanker design and now discharge of oily water is now illegal. In the past, after oil tankers discharged their cargo, they pumped sea water into the oil storage containers to provide ballast for the return trip. When the ship arrived at the loading port, this oily ballast was discharged into the ocean and crude oil was pumped into the ship's containers. Now new tankers have segregated ballast tanks. These ships have tanks that are solely used for ballast and water and oil are kept apart.

New tanker design also requires ships to have double-hull construction in accordance to the Oil Pollution Act of 1990. Double-hull construction is required on new ships built after 1993. These vessels now represent 14% of the world's tanker fleet. New tanker design also requires ships to have double-hull construction in accordance to the Oil Pollution Act of 1990. Double-hull construction is required on new ships built after 1993. These vessels now represent 14% of the world's tanker fleet.

For tanker spill information, please see The International Tanker Owners Pollution Federation Limited. For tanker spill information, please see The International Tanker Owners Pollution Federation Limited.

Go to the Topic Listing Go to the Topic Listing

Crude oil and refined products are stored in tanks for shipment to other locations or processing into finished products. There are four basic types of tanks used to store petroleum products: (1) Floating Roof Tank used for crude oil, gasoline, and naphtha, (2) Fixed Roof Tank used for diesel, kerosene, catalytic cracker feedstock, and residual fuel oil, (3) Bullet Tank used for normal butane, propane, and propylene, and (4) Spherical Tank used for isobutane and normal butane. Crude oil and refined products are stored in tanks for shipment to other locations or processing into finished products. There are four basic types of tanks used to store petroleum products: (1) Floating Roof Tank used for crude oil, gasoline, and naphtha, (2) Fixed Roof Tank used for diesel, kerosene, catalytic cracker feedstock, and residual fuel oil, (3) Bullet Tank used for normal butane, propane, and propylene, and (4) Spherical Tank used for isobutane and normal butane.

The amount of crude oil and refined products in storage is reported by Energy Information Administration. While the actual volume is important, a better index is the number of days of supply available. This number reflects the volume that can be supplied to run refineries (crude oil) or the volume of refined products that are available to meet demand.

Please click on the link Crude Oil and Product Stocks Please click on the link Crude Oil and Product Stocks

Please click on the Energy Information Administration's Topics for Petroleum Stocks Please click on the Energy Information Administration's Topics for Petroleum Stocks

Go to the Topic Listing Go to the Topic Listing

Pipelines are the most efficient method to transport crude oil and refined products. Pipelines are used to move crude oil from the wellhead to gathering and processing facilities and from there to refineries and tanker loading facilities. Product pipelines ship gasoline, jet fuel, and diesel fuel from the refinery to local distribution facilities. Pipelines are the most efficient method to transport crude oil and refined products. Pipelines are used to move crude oil from the wellhead to gathering and processing facilities and from there to refineries and tanker loading facilities. Product pipelines ship gasoline, jet fuel, and diesel fuel from the refinery to local distribution facilities.

Crude oil is collected from field gathering systems consisting of pipelines that move oil from the wellhead to storage tanks and treatment facilities where the oil is measured and tested. From the gathering system the crude oil is sent to a pump station where the oil delivered to the pipeline.

The pipeline may have many collection and delivery points along route. Booster pumps are located along the pipeline to maintain the pressure and keep the oil flowing. The delivery points may be refineries, where the oil is processed into products, or shipping terminals, where the oil is loaded onto tankers. The pipeline may have many collection and delivery points along route. Booster pumps are located along the pipeline to maintain the pressure and keep the oil flowing. The delivery points may be refineries, where the oil is processed into products, or shipping terminals, where the oil is loaded onto tankers.

A pipeline may handle several types of crude oil. The pipeline will schedule its operation to ensure that the right crude oil is sent to the correct destination. The pipeline operator sets the date and place when and where the oil is received and the when the oil will arrive at its destination. Crude oil may also move over more than one pipeline system as it journeys from the oil field to the refinery or shipping port. Storage is located along the pipeline to ensure smooth continuous pipeline operation.

After crude oil is converted into refined products such as gasoline, pipelines are used to transport the products to terminals for movement to gasoline stations. In addition to gasoline, products pipelines are used to ship diesel fuel, home heating fuel, kerosene, and jet fuel. Because product pipelines are used to move many different products, the different types of products are shipped in batches. After crude oil is converted into refined products such as gasoline, pipelines are used to transport the products to terminals for movement to gasoline stations. In addition to gasoline, products pipelines are used to ship diesel fuel, home heating fuel, kerosene, and jet fuel. Because product pipelines are used to move many different products, the different types of products are shipped in batches.

Batching is used to move two or more different liquids through the same pipeline. The liquid are transported in a series of batches. The adjoining batches mix where they come into contact. This mixed stream may be sent to refinery for re-refining, sold as a lower valued product such as a mixture of premium unleaded gasoline with regular unleaded gasoline, or sold as mixture. Many product pipelines have standard product specifications. This allows one company to ship gasoline over the line and get not be concerned whether he receives gasoline from that same batch. Its all the same quality. Individual additive packages are added at the distribution terminals.

Go to the Topic Listing Go to the Topic Listing

The Keystone Pipeline

Under Development

Latest Developments

Go to the Topic Listing Go to the Topic Listing

Crude Oil Rail Shipments

Under Development

Latest Developments

|

US safety board: Oil train tank cars need upgrades - The National Transportation Safety Board has issued a series of recommendations that could include ceramic thermal blankets that shield it from heat in case of a fire. The Board is seeing that when cars are punctured that can cause a fire and then an explosion in the other cars. - PennEnergy - 4/7/15

|

|

New rules take effect for North Dakota crude oil shipments - The new rules went into effect on Wednesday and will require companies to remove certain liquids and gasses from oil train shipments. - PennEnergy - 4/1/15

|

|

Train carrying crude oil derails in Northern Ontario - Oil & Gas Journal - 3/9/15

|

|

Texas releases details on crude transportation from Bakken region - Oil & Gas Journal - 3/2/15

|

|

West Virginia oil train derailment: Fires for hours, smoke - Train with 100 tanker cars carrying Bakken crude oil derailed and caught fire. - PennEnergy - 2/17/15

|

|

Texas officials have decided to release records from BNSF and Kansas City Railroads on rail cars carrying crude oil. PennEnergy - 2/13/15

|

|

Responding to a series of fiery train derailments, federal regulators said Wednesday they will propose that trains carrying crude oil should have at least two-man crews and requirements aimed at preventing parked train cars from coming loose and causing an accident like one in July that killed 47 people. - 4/9/14

|

Go to the Topic Listing Go to the Topic Listing

World Oil Transit Chokepoints

In 2011, total world oil production amounted to approximately 87 million barrels per day (bbl/d), and over one-half was moved by tankers on fixed maritime routes. By volume of oil transit, the Strait of Hormuz, leading out of the Persian Gulf, and the Strait of Malacca, linking the Indian and Pacific Oceans, are two of the world's most strategic chokepoints.

The international energy market is dependent upon reliable transport. The blockage of a chokepoint, even temporarily, can lead to substantial increases in total energy costs. In addition, chokepoints leave oil tankers vulnerable to theft from pirates, terrorist attacks, and political unrest in the form of wars or hostilities as well as shipping accidents that can lead to disastrous oil spills. The seven straits highlighted in this brief serve as major trade routes for global oil transportation, and disruptions to shipments would affect oil prices and add thousands of miles of transit in an alternative direction, if even available.

Please see World Oil Transit Chokepoints report prepared by the Energy Information Administration for more information. Please see World Oil Transit Chokepoints report prepared by the Energy Information Administration for more information.

Go to the Topic Listing Go to the Topic Listing

In the News

|

Four-mile slick lines California coast after oil pipeline spill - A broken onshore pipeline spewed oil down a storm drain and into the Pacific Ocean for several hours before it was shut off, creating a slick some 4 miles long across a scenic stretch of central California coastline, officials said. - PennEnergy - 5/20/15

|

|

US House poised to pass oil pipeline bill as court clears way - "Nebraska's highest court tossed out a lawsuit Friday challenging the approval of the pipeline's route through that state, a decision that could change some of the dynamics in the political tug-of-war." - PennEnergy - 1/9/15

|

|

White House says it will veto bill to approve pipeline - The White House threatened to veto the first piece of legislation introduced in the Republican-controlled Senate, a bill approving the much-delayed Keystone XL oil pipeline, in what was expected to the first in many confrontations over energy and environmental policy. The two main sponsors, Sen. Joe Manchin, D-W.Va., and Sen. John Hoeven, R-N.D., said Tuesday morning they had enough votes to overcome a filibuster of the bill but not a presidential veto. - PennEnergy - 1/6/15

|

|

Texas Railroad chairman applauds Gulf Coast oil pipeline - 2/26/14

|

|

The construction of a planned natural gas pipeline in Kentucky has been delayed until 2016 - 2/20/14

|

|

Alaskan natural gas pipeline project may cost up to $65 billion - 1/17/14

|

|

ห้ามพลาด 12 สล็อตเว็บตรงแตกหนัก อัพเดต 2024

|

Go to the Topic Listing Go to the Topic Listing

References

Check out the following references to learn more about drilling operations: Check out the following references to learn more about drilling operations:

|

, Thomas O. Miesner and William L. Leffler.

|

Click on the following links to learn more about oil transportation: Click on the following links to learn more about oil transportation:

Go to the Topic Listing Go to the Topic Listing

Copyright 2000

PetroStrategies, Inc.

All Rights Reserved

|

PetroStrategies, Inc.

PetroStrategies, Inc.