PetroStrategies, Inc. PetroStrategies, Inc. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

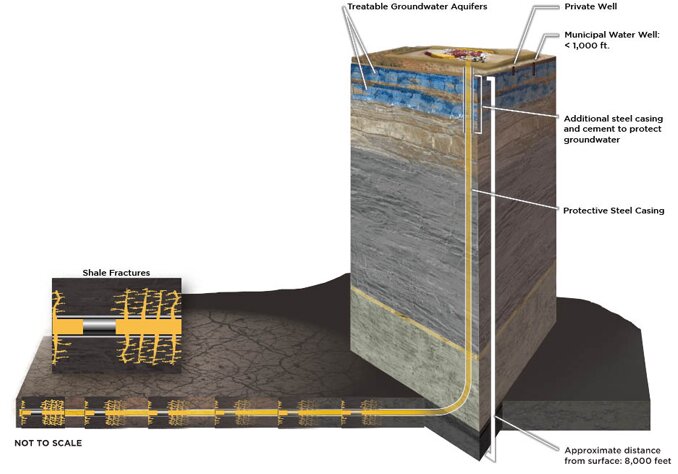

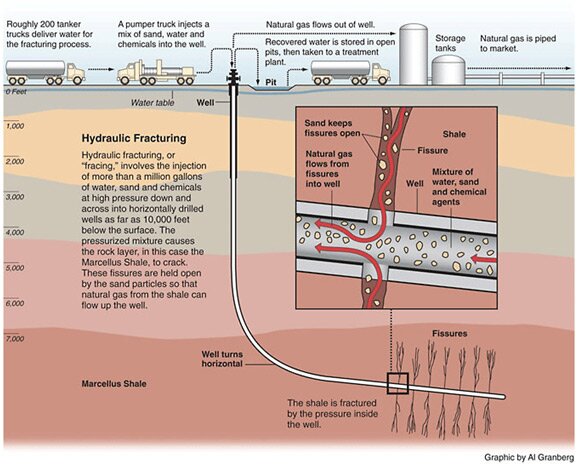

Hydraulic Fracturing Operations TopicsHydraulic FracturingThe majority of the nation�s new natural gas wells do not produce gas at sufficient rates to make the well economical. Hydraulic fracturing is a technique used to allow natural gas and crude oil to move more freely from the rock pores where it is trapped to a producing well so it can be brought to the surface at higher rates. Hydraulic fracturing technology was developed in the late 1940s and has been continuously improved upon since that time. In a hydraulic fracturing job, �fracturing fluids� or �pumping fluids� consisting primarily of water and sand are injected under high pressure into the reservoir. Most of the fracturing fluid (99% of the liquid phase) is water. Some fracturing fluid also contains a �gelling agent� to make the fluid more viscous to carry the sand (or �proppant�) and accommodate the high-pressure. The proppants are used to hold the fractures, made by the injection of the fluids, open and create new pathways for the oil or gas to flow from the rock to the well bore. Fracturing fluids may also contain very limited amounts of other materials depending on the nature of the formation being fractured. The fluid is pumped into a well bore at high pressures to create fractures in the producing formation. Most of the fracturing liquids are recovered as the oil and gas are produced and do not remain in the ground. Hydraulic fracturing is considered a stimulation treatment routinely performed on oil and gas wells in low-permeability (having fewer connecting tunnels between the pores containing the oil and gas) reservoirs. Specially engineered fluids are pumped at high pressure and rate into the reservoir interval to be treated, causing a vertical fracture to open. The wings of the fracture extend away from the wellbore in opposing directions according to the natural stresses within the formation. Proppant, such as grains of sand of a particular size, is mixed with the treatment fluid to keep the fracture open when the treatment is complete.

(Source: Hydraulic Fracturing Process, Chesapeake Energy)

(Source: What is Shale Gas and Why is it So Important?, EIA) Fracturing FluidA fluid injected into a well as part of a stimulation operation. Fracturing fluids for shale reservoirs usually contain water, proppant, and a small amount of nonaqueous fluids designed to reduce friction pressure while pumping the fluid into the wellbore. These fluids typically include gels, friction reducers, crosslinkers, breakers and surfactants similar to household cosmetics and cleaning products. The additives are selected for their capability to improve the results of the stimulation operation and the productivity of the well. ProppantProppants are particles mixed with fracturing fluid to hold fractures open after a hydraulic fracturing treatment. In addition to naturally occurring sand grains, man-made or specially engineered proppants, such as resin-coated sand or high-strength ceramic materials like sintered bauxite, may also be used. Proppant materials are carefully sorted for size and sphericity to provide an efficient conduit for production of fluid from the reservoir to the wellbore Environmental ConcernsIn April 2011, a report was issued by congressional Democrats that accused oil and gas companies of injecting "hundreds of millions of gallons of hazardous or carcinogenic chemicals into wells in more than 13 states" during 2005 to 2009. The chemicals were injected as fracturing fluids in the hydraulic fracturing operation. Hydrofracturing has attracted increased scrutiny from lawmakers and environmentalists because of concerns that the chemicals used can contaminate underground water aquifers. The report has also cited companies for "injecting fluids containing chemicals that they themselves cannot identify." The report said that more 650 of the products used in fracturing fluids contained chemicals that are known or possible human carcinogens. Companies injected large amounts of hazardous chemicals including 11.4 million gallons of fluids containing at least on of the toxic BTEX chemicals, benzene, toluene, ethylbenzene, and xylene. Another report said that the spent hydrocracking fluids are being processed in treatment plants not designed to fully treat the waste before it is discharged into rivers. At one plant in Pennsylvania, the EPA found levels of benzene roughly 28 times higher than the federal drinking level in treated wastewater discharged into the Allegheny River. (Source: "Oil, gas drillers injected chemicals, report says," The Dallas Morning News, April 17, 2011, p. 9A) Governor Tom Corbett announced plans to implement numerous recommendations of the Marcellus Shale Advisory Commission, including changes to enhance environmental standards, an impact fee, and a plan to help move Pennsylvania toward energy independence. As a part of this proposal, Corbett announced a series of prudent standards related to unconventional drilling, including:

This plan will also allow for an impact fee, which will be adopted by counties for use by local communities experiencing the actual impacts of the drilling. The fee will be used by local governments, counties and state agencies that respond to issues that arise as a result of Marcellus Shale gas drilling. Each well will be subject to a fee of up to $40,000 in the first year, $30,000 in the second year, $20,000 in the third year and $10,000 in the fourth through tenth years, adding up to a potential total of $160,000 per well. The impact fee is estimated to bring in about $120 million in the first year, growing to nearly $200 million within six years. Under this proposal, a county may provide for a fee credit of up to 30 percent if the driller makes approved investments in natural gas infrastructure, which include setting up natural gas fueling stations or natural gas public transit vehicles. The impact fee revenues will be split with 75% retained at the local level, with 36% of that number retained by the county, 37% distributed to municipalities that host the drilling pads and 27% distributed to all the municipalities within a Marcellus drilling impacted county. The distribution formula will be based on population and highway miles. The remaining 25% of the fee would be divided, with 70% of that number going to PennDOT for road, bridge, rail and other transportation infrastructure maintenance and repair within counties hosting Marcellus natural gas development, 4.5% to the Pennsylvania Emergency Management Agency for emergency response planning and training, and 3.75% to the Office of State Fire Commissioner for training programs for first responders and for specialized equipment necessary for emergency response. In addition, 3.75% will go to the Department of Health for collecting and disseminating information, and for health care and citizen provider outreach and education, and for investigating health complaints and other activities associated with shale development, 7.5% to the Public Utility Commission to enhance pipeline safety and increase inspections, and 10.5% to a restricted account at the Department of Environmental Protection to be used for plugging abandoned and unused gas wells, plus other natural gas related regulation and enforcement. Corbett said that under this plan, counties and municipalities may use these funds on various expenses related to impacts from natural gas development, including:

Corbett�s proposal also seeks to help secure energy independence and reduce reliance on foreign oil by developing �Green Corridors� for natural gas vehicles with refueling stations at least every 50 miles and within two miles of key highways; by amending the PA Clean Vehicles Program to include �bi-fuel� vehicles (diesel and natural gas); by helping schools and mass transit systems to convert fleets to natural gas vehicles; by stabilizing electric prices by using natural gas for generating electricity; and by encouraging the development of markets for natural gas and natural gas byproducts, such as within the plastics and petrochemical industries. (Source: Pennsylvania Governor Corbett proposes new Marcellus Shale regulations, PennEnergy, October 4, 2011.) Earthquakes and Fracking Operations

References

Copyright 2000 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||